Green Manufacturing: The Business Benefits Of Sustainability

Team Thomas April 19, 2022

By 2050, the U.S. Energy Administration estimates the manufacturing process will see a 26% increase in emissions, but other high-producing sectors will decrease or remain at their current output.

It's a shocking figure given that more major players are driving toward a sustainability goal — like McDonald's, who plans to have 100% of their guest packaging come from renewable, recycled, or certified sources by 2025 —but we need to continue seeing this trend moving through supply chain.

If anything, this figure and what's needed for our future presents the opportunity to produce new product options, tap into new markets, and modernize your business.

Let's unpack this together, shall we?

Lean Manufacturing & The Green Supply Chain

The traditional view of "lean manufacturing" is a way to be more efficient, strip waste from operations, and improve the company financials.

But lean manufacturing has been optimized through AI and the Internet of Things and has paved the way for green manufacturing, integrating environmental considerations into lean initiatives. Now, a purpose-driven value for businesses to meet consumer demands, sustainability and the environment have grown to be a focus for buyers — reflected in the buyer behavior data on Thomasnet.com, which shows the demand for green products such as sustainable packaging and material continues to climb.

Because buyers from large businesses are looking for sustainable products and services and partners that share their commitment to sustainability, adopting green policies and initiatives can give you a substantial leg up during the supplier evaluation process.

Manufacturers need to agile in today's competitive market, the most cost-effective, most durable/reliable, and the highest quality, with superior service and support.

What Are The Benefits Of Going Green In Manufacturing?

This ability to attract more buyers and win more business is the most obvious benefit of sustainability; however, it's not the only one.

Here are some additional advantages of becoming more sustainable in your operations...

Reduced Costs

Going green can help you keep more cash in your pockets, and in some ways, it can be really easy to start.

Installing energy-efficient lighting, for example, can substantially reduce your long-term electrical costs. Reducing water usage and cutting down on waste disposal needs can also add up to big savings over time.

In fact, a 2014 study by Indiana University found that one form saved $7 billion through sustainable manufacturing, while another was able to save $80 million a year by reducing its energy use.

A reduced supply chain of certified and trusted vendors is definitely cheaper than a wide variety of vendors you use sporadically. Local deliveries equal lower distribution costs. Less energy, water, and waste are less of your profit funneling into bills. In this case, less is most definitely more.

According to our surveys conducted by Thomasnet.com:

- As of June 2020, 69% of manufacturers indicate they are "likely to extremely likely" to reshore in future

- 72 percent of industrial/B2B buyers "always or generally" prefer to source locally

- In comparison, just 10.8 percent of respondents "always or generally" prefer to source globally

- In fact, nearly half of buyers (46.7 percent) actually "rarely or never" prefer to source globally at all

As other companies look to reduce costs too, see if they're looking for products and services you offer with a free in-market buyer report.

Tax Credits

Making investments in technologies like solar, wind, and geothermal heating will pay off in terms of savings in the long-term.

You can also receive a tax credit of up to 30 percent of the investment.

Brand Recognition

People want to do business with companies that are not only good at what they do, but good for the things that they care about.

Establishing your company as a champion of environmental responsibility can lift the perception of your manufacturing brand, which can play a vital role in the success of your business overall.

Attracting New Employees

As seasoned employees age out of the workforce, the manufacturing skills gap gets wider by the day.

If you don't have the right talent ready to take in and take over these vital tasks, it can be crippling for your company. One of the best ways to appeal to the next generation of workers is to demonstrate your commitment to the environment — they want to work for companies that are socially and environmentally responsible.

Contributes To The Economy

On that note, sustainable manufacturing strategies and collaboration efforts with like-minded companies defend and create American jobs.

Today's world challenges are growing increasingly complex. Businesses who work together can help address the challenges impacting society and build a stronger foundation for the economy and industrial future.

Enact a reshoring policy, lessening transportation and fuel usage in favor of local manufacturing, helping the environment and the U.S. economy.

You Might Also Be Interested In: Reshoring Is Creating Opportunities For North American Manufacturers

More Environmentally Friendly Manufacturing

The manufacturing landscape is a crowded one, and you need to do everything you can to gain a competitive advantage. Embracing sustainability and green-friendly practices is one way you can do just that — here are three examples.

Analyze Your Current Environmental Impact

The first step you need to take to become a more sustainable facility is to understand your current state. Start by analyzing your energy usage. Determine how these sources are used in your production processes and how they might influence the environment.

Another important factor to consider is your organization’s water intake. To do so, leverage resources from EPA’s Watersense or call your local water company — they can help you determine where you can cut water waste.

Finally, look at the materials you are using on the shop floor. Are they recyclable or hazardous? How necessary are they to the production process? Asking these questions can shed light on your situation and your options going forward. Once you understand where your organization stands, you can take steps towards a more environmentally friendly facility. Fortunately, these steps don't have to be giant strides; you can start small and make incremental, strategic improvements.

Learn More: Examining More Sustainable Practices In Manufacturing

Reduce Waste Where You Can

Keep efficiency in mind when using machines. Not in a room? Turn the lights off. Recycle paper and plastic. These are small everyday changes that don’t contribute greatly to the cause, but certainly fall into the “every little bit helps” bucket.

For example, consider how you buy and use raw materials. If you only need part of a raw material, explore ways to leverage what you don't use. Work with other shops in the area to see if they can use the excess materials, and see if they have any you could leverage in exchange. At the very least, recycle your unused materials instead of throwing them in a dumpster.

Regular monitoring of your resources can help you begin thinking sustainably, easing you into bigger and better changes. Document your efforts and be transparent about your efforts to your employees and customers. Think about the bigger picture.

For example, can your product development make a shift to greener pastures? Do the products you’re producing have less of an environmental impact as your competitors? Is less energy being used to power your factory? Is the material you're using biodegradable? How about non-toxic? How can you weave sustainability into your product design?

Find Ways To Leverage Renewable Energy

Leveraging renewable energy is one of the best ways to create a more sustainable facility. Renewable energy options are plentiful, and they include sunlight, wind, rain, tides, waves and geothermal heat.

According to the 2019 Clean Jobs America analysis, by the year 2035, renewable energy is expected to become the world's prominent power source. This year, solar energy costs have reached a historical low, due to technology and innovation keeping the costs down.

Major corporations such as Walmart and Anheuser-Busch InBev have already taken action by implementing renewable energy systems because it's cheaper than traditional energy sources for larger shops. In addition to saving on raw energy costs, you may also be able to take advantage of tax incentives, depending on the state you live in.

Is Your Manufacturing Company Eco-Friendly?

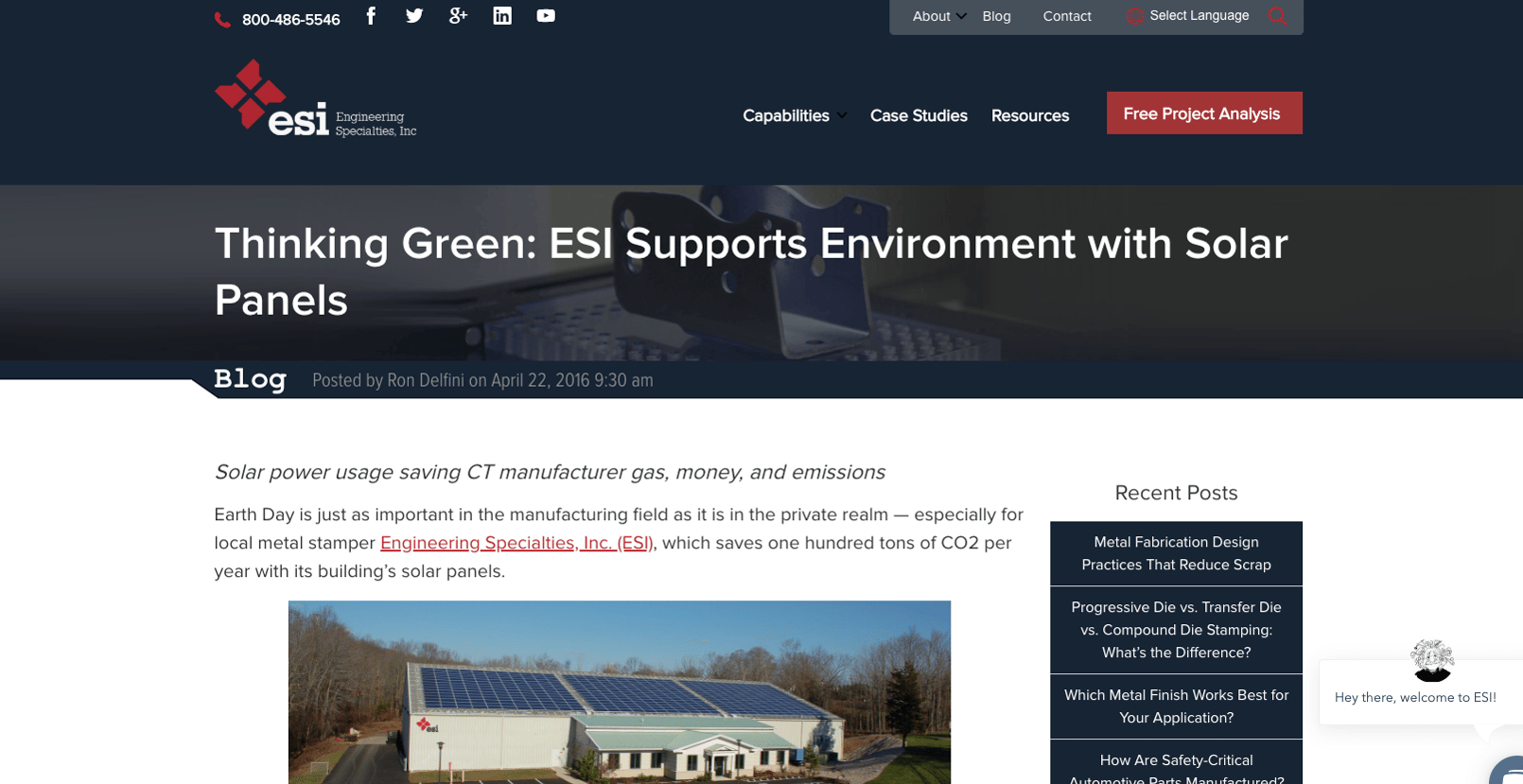

Your website is the first impression on customers. Make it the best first impression by improving your website with things buyers are looking for — including being green. In the example below, ESI showcases how their facility saves one hundred tons of CO2 per year with its solar panels. They even added a link to their live solar panel feed.

See More: 6 Small Business Green Manufacturers Committed To Sustainability

Buyers learn as much as they can about you online before they decide who to partner with, and if you're looking to attract new environmentally minded buyers, find out everything else you need to do to improve your online presence and how you compare with competitors with our free Digital Health Check.

Did you find this useful?

![How To Meet The Needs Of B2B & Industrial Buyers [Updated 2022]](https://blog.thomasnet.com/hubfs/Brainstorm%20meeting%20understanding%20B2B%20buyers.png)