How To Become A Defense Supplier

Did you know that the Department of Defense (DoD) spends more than 60 percent of the federal procurement budget eligible for small businesses? In the 2017 fiscal year, DoD awarded more than $60 billion in prime contracts to small businesses.

From anonymized sourcing activity across Thomasnet.com, Thomas Industrial Data shows the Aerospace & Defense Industry is a rapidly evolving field. Continued military spending growth is a sign for suppliers to secure ongoing business and tap into new market opportunities — but today, businesses continue to shift in their sourcing as they pivot to help the country combat COVID-19. Read on to learn how you can become a part of the solution.

Read More »

Opportunities For Lithium-Ion Battery Manufacturers

In 2019, lithium-ion sourcing activity on Thomasnet.com soared, and the B2B buyer data showed the top two industries driving the trend were software and technology, and healthcare and medical. Today, there are three major lithium-ion battery markets: transportation, electronic devices, and industrial stationary.

Technology is at the core of the transition, and the next few years will bring significant changes to the industry.

Read More »

What Manufacturers Need To Know About The Defense Production Act

On January 21, 2021, President Biden signed a series of executive orders including invoking the Defense Production Act to combat the COVID-19 pandemic. The order directs federal agencies to make use of the act to increase production of materials needed for vaccines, masks, and testing kits.

Many manufacturers and engineers have volunteered to address the shortage of supplies to combat the coronavirus pandemic throughout last year but some supplies are taking a long time to produce. Invoking the Defense Product Act (DPA) allows the federal government to direct U.S. manufacturers to ramp up production of emergency medical supplies immediately.

Last year, FEMA confirmed using the DPA for the first time during the coronavirus pandemic to order about 60,000 test kits and 500 million personal protective masks. However, FEMA then announced later that same day, “At the last minute, we were able to procure the test kits from the private market without evoking the DPA.”

The uncertainties of today's crisis coupled with manufacturers' exempt status from state-wide closures signal that the industry should remain prepared for the enactment of the DPA. Here’s what it means for U.S. manufacturers and how they can prepare.

Read More »

3D Printing And Additive Manufacturing Challenges And Opportunities

The outlook for additive manufacturing and 3D printing is promising. Back in 2017, Thomas reported on the increased sourcing activity for additive manufacturing. Although the base technology of additive manufacturing was developed in the 1980s, its use has become more prevalent in the last few years as advancements grow and prices drop. Sourcing activity sessions for additive manufacturing systems in 2020 was up 37.8% compared to 2019. And according to Statista, the global market for 3D printing and services is expected to grow to almost 50 billion U.S. dollars by 2025.

Read More »

The Evolution Of 3D Printing

From reducing costs to increasing efficiency to spurring innovation, many people are excited about the impact that 3D printing will have on the future of manufacturing. However, the truth is, it already has made a significant impact on the industry.

Take a look back at the evolution of 3D printing to see how the phenomenon started and how it has helped the manufacturing industry evolve.

Read More »

8 Reasons It’s Great To Work In Manufacturing

The manufacturing industry is one of the largest and most influential sectors of the United States economy. According to ACS estimates, the number of people employed in the Manufacturing Industry Sub-Sector has been growing at a rate of 0.41%, from 15.4M people in 2017 to 15.5M people in 2018.

But what is it like for the millions of people who actually work in the industry? The truth is, it's pretty fantastic. Here are some reasons why:

Read More »

6 Common Mistakes That Job Shops Make

For more than 120 years, Thomas has created trusting relationships with thousands of successful job shop owners from coast to coast. Job shops across America form the backbone of the country’s economy. Unfortunately, even though they may have the right skills, equipment, and people, it’s not rare to see a job shop fail.

In this blog post, we'll review the common mistakes job shops make and some anecdotal insights directly from job shop owners and managers.

Read More »

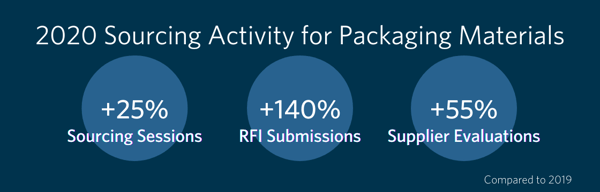

Buying Activity for Packaging Materials in 2020

Buyers are actively searching for new supplier partners for their packaging materials needs in 2020

Buying activity from engineers & procurement professionals sourcing on Thomasnet.com has seen strong growth in 2020 for the packaging materials space. At a glance, the following major sourcing KPIs have seen a YoY increase vs. 2019:

- The number of sourcing sessions for packaging materials has grown by 25%

- The number of RFIs submitted directly to suppliers through Thomasnet.com grew 140%

- The number of supplier evaluations taking place on the Thomasnet.com company profiles of packaging material suppliers grew by 55%

Manufacturing Day 2020: STEM Resources for High School and College Students

With the COVID-19 pandemic forcing many schools to shift away from in-person instruction toward a remote learning environment, the challenge of maintaining student engagement takes on increased significance. This is especially true in courses that involve STEM subjects (Science, Technology, Engineering, and Mathematics).

When taught in a traditional in-person setting, STEM courses combine education in the theoretical treatment of the subject (gleaned from written material as found in textbooks) with the practical treatment of the subject (developed via hands-on work from labs, experimentation, and the use of instruments and materials). When shifting to a remote learning environment, the techniques for educating students on the underlying principles of a subject are much easier to transfer successfully than are the more practical hands-on aspects.

To help fill this gap, we have identified some resources that may be used to provide students at the high school or college level with practical hands-on projects that they can perform which will help them supplement their education in STEM subjects.

The resources below contain a mix of different potential project ideas, many of which can be performed from home with a minimal need to purchase special suppliers or materials. Other projects from the resources below, especially those at the college level, will likely require students to make some investment in materials, components, and equipment that would not usually be found in the typical household. These are higher level projects that normally would be accomplished in a college lab class, possibly in a collaborative group setting, under the guidance of an instructor or advisor.

Read More »