Cybersecurity In Today's Interconnected Supply Chain: Don't Build An Apartment. Build A House.

Take a moment to consider all of the components of your organization’s supply chain. Commonly, quite a few capital assets come to mind: raw materials, machinery, warehousing, logistics, distribution centers, brick and mortar sites, office locations, point of sales, and so much more.

Whether it’s keeping employees connected to one another, interacting with customers, or generally exchanging data from one system to another, interconnectivity is a crucial, but risky, component of supply chain management.

And, in a world where millions of cyberattacks happen each day, companies can no longer afford to approach cybersecurity with an “if this happens” mindset, rather establish the proper structure and protocol for when it does.

Read More »

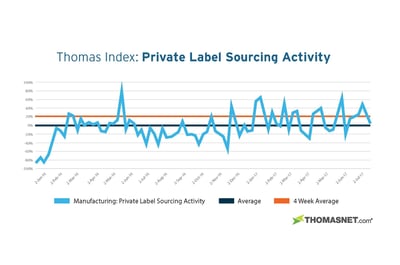

Thomas Index Report: Private Label

More B2B buying activity takes place on THOMASNET.com than any other resource on the planet. In fact, a buyer evaluates a supplier every 2 seconds on our platform.

To help buyers and suppliers stay ahead of the latest shifts and emerging trends in the digital industrial economy, we constantly analyze all of the buying activity taking place on the platform. This powerful, proprietary data fuels the Thomas Industrial Index.

Here’s what we’re seeing on the Index this week:

Read More »/Electric%20(1).png?width=400&name=Electric%20(1).png)

Managing Total Cost Of Ownership In The Electrical Supplies Category

Although each category of purchasing that falls under Maintenance, Repair, and Operations (MRO) poses its own unique challenges, electrical supplies stands out as one that appears to be tactical. However, it does grant the opportunity for significant cost savings and value enhancement when viewed from a strategic perspective.

The “Electrical Supplies” umbrella covers a broad area of products, and depending on the needs of a particular organization, the level of complexity may vary particularly with wires and cables, automation supplies, lighting, and electrical distribution equipment. From a category perspective, there are opportunities to reduce costs when determining the preferred supplier base.

Read More »/PCBs.png?width=400&name=PCBs.png)

Thomas Index Report: Printed Circuit Board Sourcing Trends

More B2B buying activity takes place on THOMASNET.com than any other resource on the planet. In fact, a buyer evaluates a supplier every 2 seconds on our platform.

To help buyers and suppliers stay ahead of the latest shifts and emerging trends in the digital industrial economy, we constantly analyze all of the buying activity taking place on the platform. This powerful, proprietary data fuels the Thomas Industrial Index.

Here’s what we’re seeing on the Index this week:

Read More »

Forklift Sourcing 101: Know Your Options, Save Money

Though they serve as critical elements in many material handling operations, forklifts can come with many potential hidden costs, such as maintenance and operator salary — in total, costs can reach as high as $250,000 annually per machine!

Despite these expenditures, more and more companies are making use of forklifts; a recent Peerless Research Group survey of material handling managers found that 69% of respondents planned to acquire a new forklift in the near future, with a per-respondent average of seven planned purchases, up from six the year prior.

Read More »/Untitled%20design%20(3).jpg?width=400&name=Untitled%20design%20(3).jpg)

The Shift To Electric Vehicles Is Accelerating – And Suppliers Should Take Notice

While electric vehicles (EVs) account for less than 1% of all vehicles sold in the United States today, two new forecasts show that this number will skyrocket in the years ahead. The shift will have a profound impact on automakers and their suppliers.

Read More ».png?width=400&name=Steel%20(1).png)

Thomas Sourcing Trends: Steel

Buyers and engineers evaluate a supplier on THOMASNET.com every 2 seconds. All of that sourcing activity gives us valuable insight on the movements of typical patterns in the industrial market place.

Over the past few months, we've been watching raw material sourcing closely and we've noticed some interesting trends:

Read More »

Reduce Costs in Product Design Through Raw Materials

It is often later in the product lifecycle that procurement teams are brought in to lead a competitive bid process and conduct negotiations accordingly. This might seem like a straightforward approach to reducing costs. However, taking a deeper look at your product design and raw materials before the manufacturing phase could be the best way to proactively optimize costs.

Read More »

The BMW Supply Chain Breakdown: What Happened?

It's no secret that having transparency into your supply chain is essential to mitigating risk. In fact, companies are investing in supply chain visibility and collaboration tools at a faster rate than any other supply chain discipline, putting their money where their risk is.

Clearly, companies are taking transparency seriously in an effort to stay plugged in to their suppliers. However, in order to ensure a strong, steady and productive supply chain, having visibility into your own suppliers isn't enough – you need to have visibility into their suppliers as well. This is especially true in industries that are driven by outsourcing in an effort to lower costs and shift production requirements.

Read More »