Industrial Icons: Valmont Coatings Reaches a Range of Marketing Segments With the Help of Thomas

Tricia Contreras February 16, 2026

Thomas has been connecting industrial buyers and suppliers for more than 125 years. The Industrial Icons blog series celebrates the longtime customers who have grown their businesses with Thomas and the marketing and advertising solutions that have evolved along with them over the years.

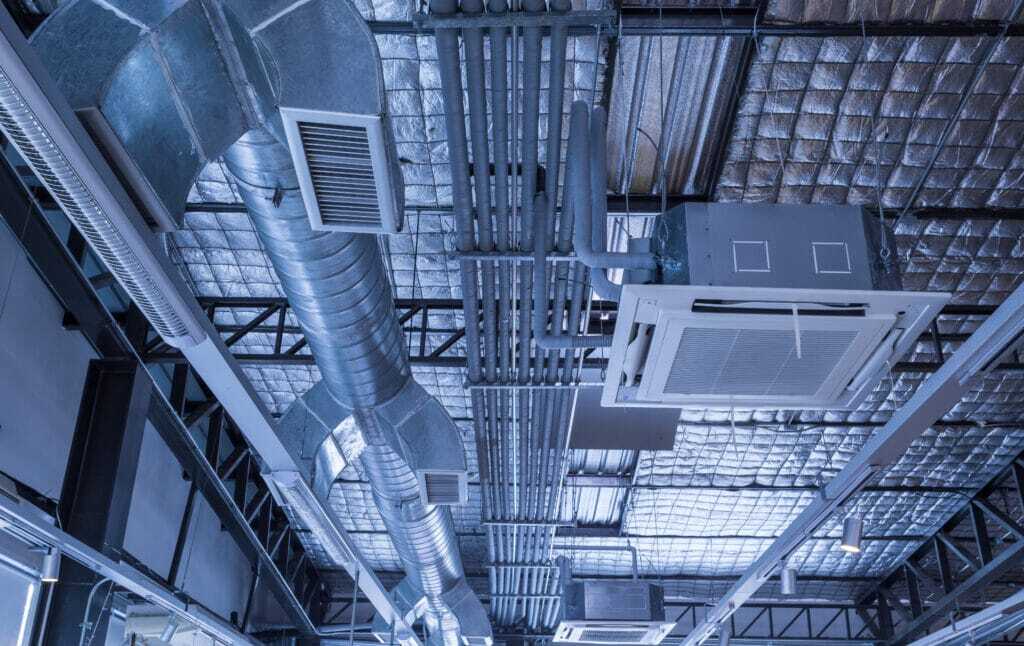

Countless pieces of industrial equipment rely on protective coatings to shield them from the elements and maintain their integrity. Valmont Industries, Inc. earned a reputation for dependability and durability due to the high-quality corrosion protection of its irrigation products, spurring the company to launch an entire business unit dedicated to coatings.

Today, Valmont Coatings operates more than 35 coatings facilities across seven countries. Its Salina, Kansas, facility is home to one of the largest galvanizing kettle (by volume) in the world. Representing North America Coatings at Valmont Industries, Director of Sales and Marketing Amanda Swanberg and Marketing Specialist Amy Nelson discuss how working with Thomas has helped the company get in front of the right audience and secure high-quality leads.

How and when did you get started advertising with Thomas?

Swanberg: Valmont Industries has worked with Thomas since 2010, and I got connected with a rep back in 2016. Right from the beginning, I've found that Thomas has some of the best representatives and the best customer service folks that help make the process easy and fun. We saw strong traffic originating from Thomas to our website, and I've always felt that the traffic coming from Thomas results in our highest quality leads compared to a lot of other platforms.

Swanberg: Valmont Industries has worked with Thomas since 2010, and I got connected with a rep back in 2016. Right from the beginning, I've found that Thomas has some of the best representatives and the best customer service folks that help make the process easy and fun. We saw strong traffic originating from Thomas to our website, and I've always felt that the traffic coming from Thomas results in our highest quality leads compared to a lot of other platforms.

What have been the biggest wins in your journey with Thomas so far?

Nelson: Being in front of the right audience and being able to reach engineers and manufacturing companies has helped us the most.

Nelson: Being in front of the right audience and being able to reach engineers and manufacturing companies has helped us the most.

Swanberg: It's really the web traffic. When we do see an inquiry come directly from Thomas, they're always exactly what we're looking for. They're inquiring about the services we offer, and they’re real opportunities, which is ultimately what we're looking for at the end of the day.

The company announcements in Thomas Industry Update have been great as well. The first one we ever did was to announce our newest facility, Pittsburgh Galvanizing. It definitely got some attention.

What’s something you’ve learned from working with Thomas?

Nelson: Thomas has reinforced the importance of educational content and educating manufacturers by giving them real-world applications. We can share case studies or we can share videos about our industry. It allows us to tell our story. We can showcase galvanizing as a long-term solution and connect with the right people.

Swanberg: For me, the biggest lesson learned has been around Thomas’ WebTrax™ tool. [WebTrax is a proprietary analytics tool that gives Thomas customers insights into activity on their company websites, including buyer intent signals and in-market buyer activity.] I was somewhat familiar with Google Analytics when I started working with Thomas, but having Thomas representatives walk me through WebTrax had an impact on how quickly I learned some of those metrics and helped me better evaluate what they mean to our business.

What’s a trend you’re seeing in your industry/sector right now? How are you adapting your marketing strategy to meet that trend?

Swanberg: Our audience has been in transition for a while in terms of how they consume information based on their age bracket. In our business, a lot of facilities serve mom-and-pop shops that want the traditional in-person relationship and personal phone calls. I assume most of manufacturing is going through a similar transition – as that baton is passed to the next leader, they have a drastically different way of doing business. That means an increase in our emphasis on digital, since more and more people are consuming information that way, and making sure we stay on top of AI, while still having the ability to nurture the folks who prefer traditional methods of doing business. All of this has forced us to have a broader view of marketing and sales overall, to ensure we hit all of those market segments.

Nelson: We’re focused on educating the next generation. We work alongside the American Galvanizers Association to strategize ways to reach the next generation of specifiers and engineers in the industry. We do outreach at universities and student organizations by giving lunch-and-learn seminars. We've even reached elementary school students by creating experiments and activities to demonstrate that galvanizing is the most durable solution. It’s about creating engagement and keeping our industry top of mind for the next generation.

Manufacturing has proven to be an enduring industry in America, even amid political and economic changes. What gives you hope for the future of the industry?

Swanberg: Galvanizing protects our nation's critical infrastructure. As we continue to grow as a nation, that infrastructure needs to be reliable. Inevitably, there will be cycles of replacement and upgrades, for which there's a huge demand for galvanized steel.

When it comes to sustainability, zinc and steel have the highest reclamation rates of anything that can be reused and recycled, so they hit those sustainability markers while also being extremely long-lasting and durable. We're well-positioned to grow with America moving forward. There's also a huge demand to replace infrastructure with longer-lasting materials. So, there’s a lot of hope and opportunity in our industry.

Image credit: Valmont Coatings

Did you find this useful?