Information Technology Challenges In The Manufacturing Industry

Shalane Layugan July 22, 2021

The current business climate is driving manufacturing companies to build a more digital and data-driven workforce. As the industry adopts more technologies and influences the future of American manufacturing, what challenges are they continuing to face and how can they guide their organizations strategically?

Adoption Of Automation For Processes And On Plant Floors

Industry 4.0 is what is referred to as the Internet of Things, or IoT, and during the past few years it has introduced a new era of technologies to transform the way industry operates, like the adoption of robots.

For the meat manufacturing industry, adoption of automation has been comparatively slow, but largely because it has proven difficult to develop robots that can effectively and accurately perform the work of human workers. In addition, there has been a controversial history of robots in industrial facilities (the first robots in facilities were caged to prevent injuries). And in recent years, several automation initiatives within meatpacking companies have been abandoned due to increased wastage of high-value meat. But the COVID-19 pandemic has catalyzed meat manufacturers and other industries to move toward the direction of technology adoption and integration.

According to a recent industrial survey, more than half of the companies surveyed reported that they meet or exceed the industry standard for automation, with 55% of the participants being “likely” to “very likely” to invest in Production Performance Automation in the next 12 months. It’s no secret that automation and other technologies are worth it in almost every manufacturing facility type, but companies must remain proactive.

According to a report from MHI in conjunction with Deloitte, skilled individuals are hesitant to work for companies that haven’t fully adopted digital technologies. To bridge the digital and IT skills gap and fill advanced roles, consider reverse mentoring, promoting technology goals and utilizing upskilling and reskilling. Most companies are familiar with traditional mentoring programs that involve an older generation worker who shares professional or personal experiences with a younger employee. But in reverse mentoring, a younger employee educates the more experienced colleagues on digital skills and how to use certain technologies, including online marketing efforts.

Calculating ROI can be difficult if you’re new to digital ads or inbound marketing. Begin by setting analytic tools like Google Analytics and Thomas WebTrax and record your current efforts in reports. Take a look at current industry benchmarks to track how well your efforts are faring and what opportunities you can improve on. Not all leads are the same and proper digital reporting and analytics in place will help to solve the challenges of managing leads and generating engagement from engineers, procurement managers, and MRO professionals.

Using Data To Improve Decision-Making

Most businesses have access to the same set of data sources, like website analytics or app monitoring, to make decisions. Other traditional data can be collected in-house through metadata from emails, memos, and contracts to provide insight into communication trends and industry benchmarks.

When supplemented with traditional data, alternative data gives a unique insight to make more accurate predictions. A typical function of alternative data is using it to identify efficiencies in processes and ways to improve net returns. And while alternative data has steadily become mainstream in finance industries, other sectors are reaping the benefits too and adopting data-driven growth strategies. Because of its impact on the economy as a whole, data around manufacturing has been of particular interest to decision-makers who seek to develop a better understanding of predictions and what opportunities are available.

In a recent Thomas podcast, guests Mark Heidebrecht and Sam Bradbury, the two board-certified ergonomists advised to use data to propel your business forward. “There is a lot of data out there. I would caution this by saying there is a lot of bad data out there as well. But if you can find a good data source that gives you good, reliable information to make your decisions, you want to go with a data-driven process that allows you to make good decisions that support the outcomes you're trying to achieve,” Mark Heidebrecht said.

Today, more manufacturers are using data and automation to improve safety. But some manufacturers may be challenged with how to convert their data into actionable items. Invest in tools that can tell you exactly how much risk you’re taking on by bringing technologies into your facilities.

The Thomas Manufacturing Index (TMX) sheds light on key dynamics that drive market performance by measuring industrial activity in the United States and Canada from a diverse set of companies, including Fortune 1000, mid-market, and SMBs. Click here to learn how you can use Thomas purchase and sourcing intent data from over 1.3 million in-market industrial and commercial buyers to help sharpen your strategies. Here are some additional resources on overcoming industry challenges and working with data:

- The Latest Sourcing Activity Report: What Are The Most Sourced Industrial Products & Services

- Industry Executive Explains Why the Future of Manufacturing Will Be Human-Machine Collaboration, Not Robots Replacing Human Workers [Q & A Interview]

- Top 4 U.S. Manufacturing Challenges And How To Overcome Them

- 4 Tips to Ensure a Successful Warehouse Robotics Implementation

Managing Cybersecurity

Due to the in-person limitations of COVID-19, 84% of recently surveyed manufacturers are using their website more to generate new customers — in contrast to 72% before the pandemic. With the increasing use of technological advancements, manufacturing leaders should be aware that their industry is one of the most targeted by cyber attackers. In fact, studies show that cybercriminals are shifting away from targeting the financial sector and now targeting manufacturers. Moreover, according to EEF (formerly the Engineering Employers' Federation), over 45% of the manufacturers have been subjected to a cybersecurity incident.

Videos and online chats are more prominently being used now, and you’ll want to make sure your employees are using secure internet connections to protect your business and your customers.

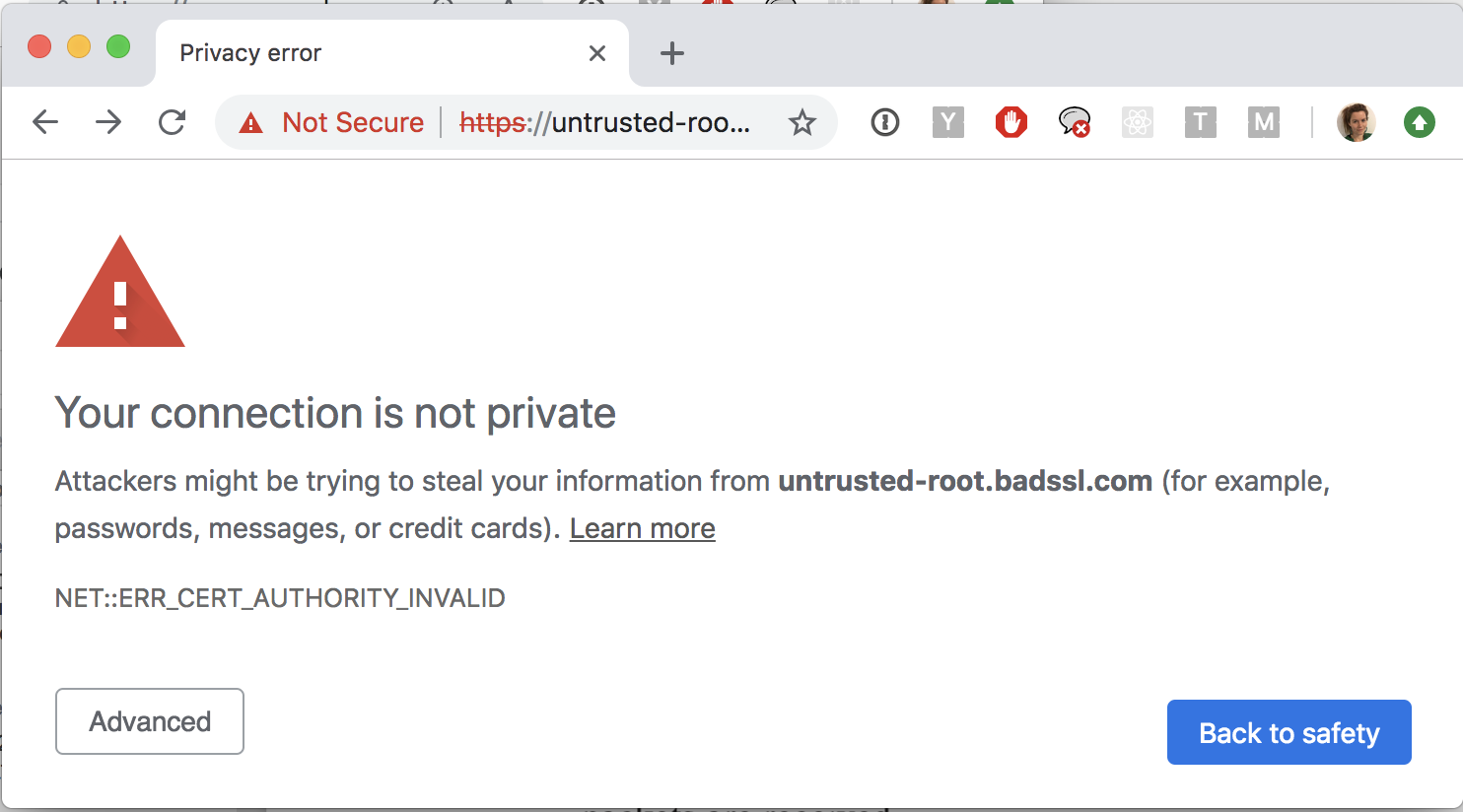

At a minimum, manufacturers should have a secure website. Buyers, procurement professionals, engineers, and other purchase decision-makers expect a seamless, secure experience when sourcing suppliers and products online. But if your website is not set up with basic components like secure HTTPS encryption, and prospects see a warning like the image below, they may turn to a competitor.

HTTPS is a way to encrypt data that is sent between a browser and a web server, preventing unauthorized third parties from accessing that data while it’s in transit — and it's important in today's business world where more than 70% of B2B buyers are tech-savvy millennials. HTTPS curbs the risk your users face of falling prey to a number of cyberattacks and scams, including “man-in-the-middle” attacks — where scammers siphon information that users have entered on your site, such as credit card numbers, usernames, passwords, etc. — as that information is sent to your web server.

Think of sending sensitive data over just HTTP as sending a postcard with your passwords on it — anyone handling it between you and the recipient can read it. Sending sensitive data over HTTPS is more secure, like sending your passwords in a security envelope inside of a box inside of a safe.

HTTPS Misconceptions For Manufacturers

Encryption technology has been around for more than two decades. More and more companies have shifted their business models to the web, where they actively collect information from their visitors. While these interactions don’t necessarily involve credit cards or social security numbers, there is more data flowing from web browsers to web servers than ever before. The rise in encryption adoption is, at least in part, tied to the rise in the opportunities for encryption. While many of the reasons that deterred companies from switching to HTTPS are no longer applicable, some common misconceptions do still exist, including these:

Switching To HTTPS Costs Too Much

An encryption certificate used to cost upwards of $1,000 a year, which was prohibitive for many small businesses. However, costs today can cost a few hundred dollars annually, and many hosting companies provide security certificates at no cost.

💡 Thomas Tip: If you host with Thomas, we'll set it all up, do redirects, and launch your website for you at a low cost. Request a free digital health check and we'll let you know exactly what your website needs to be up to date and within your budget.

My Manufacturing Business Doesn't Need HTTPS

Let’s go over this again: if you collect any data from your visitors, if you don’t want to scare off potential customers, and if you want to put your company in the best position to attract new clients, then you do need to be encrypted.

Implementing HTTPS Is Too Complicated

So this reason is still somewhat accurate. You do need to be comfortable installing your certificate, updating your registry and hosting information, and implementing HTTPS with your CDN, if you have one. After you do that, you’ll need to redirect and update old links to ensure that nothing gets lost in transition. This process takes some time and technical know-how, for sure. However, some hosting companies offer simple tools that allow you to add HTTPS to your website with only one click — or partner with industrial marketing experts who have knowledge in your sector.

You may also be interested in:

- How to Protect Your Manufacturing Assets Against the Growing Threat of Cybercrime

- 6 Best Practices For Supply Chain Cybersecurity

How The Manufacturing Industry Can Overcome Technology Challenges

To outperform competitors in today’s highly connected, digital world, it’s important to actively engage incoming and existing workers on ways to stay relevant, efficient, and aware of what’s changing in the IT world. Educate your employees on cybersecurity risks if they're working on computers and technical systems. Last year pandemic-related fraud was up 400%. To further maintain cybersecurity for those manufacturers who have shifted to remote work, make sure you limit employee access to sensitive data, implement zero-trust capabilities, and conduct regular backups.

Thomas has resources and expertise to help you overcome those challenges and ensure you're technology-driven not just for the short term, but sustainably for years to come. Request a free digital health check to see exactly how you can improve your digital efforts.

See more related articles on the state of the industry:

- 2020 Industrial Marketing Benchmarks For Manufacturers & Distributors

- The Latest Industrial Activity Through The New Thomas Manufacturing Index

- Manufacturer Interest in Reshoring, Hiring, and Apprenticeships Increasing During COVID-19 Pandemic [Report]

Dive into other industry-focused articles:

- Challenges And Opportunities In The Aerospace Industry

- Challenges And Opportunities In Private Labeling

- Challenges And Opportunities In Medical Device Manufacturing

- Challenges And Opportunities In Pharmaceutical Manufacturing

- Challenges And Opportunities In Cannabis Industry

- How To Grow Your Steel And Metals Company

- Challenges And Opportunities In The Food And Beverage Industry

- How To Grow Your Textiles Manufacturing Company

- 11 Tips For Growing Your CNC Machining Business

- How To Increase Sales For Your CNC Machine Shop

- How Can Private Label Manufacturers Increase Sales

Did you find this useful?